- 네소개- 네

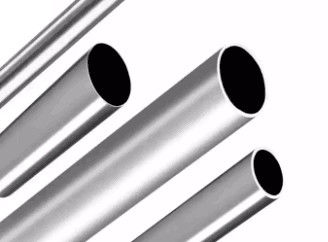

ASTM A213는 전 세계적으로 인정되는 표준으로톱니없는 페리틱 및 오스텐리틱 합금 철강 파이프높은 온도 서비스용으로 설계되었습니다.T11(일부 지역 표준에서 12Cr1MoV로 지정되기도 합니다.) 는 특별한 강도, 열 안정성,고온에서 미끄러지는 저항성전력 생산, 석유화학 및 중공업 부문에서 널리 사용되는 T11 튜브는 화석 연료 및 복합 사이클 발전소의 극한 조건에 견딜 수 있도록 설계되었습니다.현대 에너지 인프라에 필수적인.

이 문서에서는 ASTM A213 T11 튜브의 기술적 특성, 제조 공정, 품질 관리 조치 및 실제 응용 방법에 대해 자세히 설명합니다.고온 엔지니어링 시스템에서의 역할에 대한 상세한 분석.

- 네1. ASTM A213 T11의 화학적 성분- 네

T11 튜브의 기계적 및 열적 성능은 근본적으로 ASTM A213에 의해 엄격하게 규제되는 정확한 화학적 구성에 의해 결정됩니다.주요 요소와 그 전형적인 범위는 아래에서 설명됩니다.:

|

원소

|

구성 범위 (%)

|

목적/효과

|

| 탄소 (C) |

≤ 0.08~0.12 |

강도를 향상시킵니다; 더 높은 탄소는 경직성을 향상시키지만 용접성을 감소시킬 수 있습니다. |

| 크롬 (Cr) |

10.00150 |

높은 온도에서 산화 및 염화 저항성을 향상시키기 위해 수동 산화층 (예: Cr2O3) 을 형성합니다. |

| 몰리브덴 (Mo) |

0.44'065 |

고체 용액 경화 및 곡물 정제로 물질을 강화합니다. 미끄러지기 저항에 중요합니다. |

| 망간 (Mn) |

0.30 ∼ 0.60 |

경화성 및 견고성 향상; 뜨거운 깨지기성을 줄이기 위해 황을 중화합니다. |

| 실리콘 (Si) |

0.17 ∼ 0.37 |

철강 제조 중 산화 방지제; 고온 강도를 향상시킵니다. |

| 포스포스 (P) |

≤ 0.025 |

불순물, 깨지기 방지하기 위해 통제 |

| 황 (S) |

≤ 0.010 |

불순물, 열로 융통성 및 용접성을 향상시키기 위해 최소화 |

| 니켈 (Ni) |

≤ 0.30 |

미량 원소; 특정 열 처리 조건에서 강도를 높일 수 있습니다. |

| 바나디움 (V) |

≤ 0.20 |

선택 사항입니다. 곡물 구조를 정제하고 미끄러지기 저항성을 높입니다. |

- 네핵심 참고:T11의 균형 잡힌 구성이 크롬과 몰리브덴을 주요 합금 요소로 함으로써 고온 강도, 산화 저항성,용광 피로 저항성, 낮은 합금 또는 불합금 강철에서 구별합니다.

- 네2. 물리적 및 기계적 특성- 네

ASTM A213 T11 튜브는 높은 온도 (760°C / 1,400°F까지) 에서 지속적인 성능이 중요한 환경에서 작동하도록 설계되었습니다.그들의 특성은 ASTM 표준에 따라 엄격한 테스트를 통해 검증됩니다..

- 네2.1 방온 속성- 네

- •

- 네팽창 강도 (UTS): ≥ 415 MPa (60,200 psi)

- •

- 네양력 강도 (YS):≥ 205 MPa (29,700 psi)

- •

- 네길쭉함:≥ 20% (50mm 또는 2in)

- •

- 네딱딱함:≤ 170 HB (Brinell) 또는 ≤ 175 HV (Vickers)

이 값은 재료가 설치 및 초기 서비스 단계에서 기계적 스트레스에 견딜 수 있음을 보장합니다.

- 네2.2 고온 성능- 네

T11의 결정적 장점은 높은 온도에서 동작하는 데 있으며, 대부분의 강철은 스크립 (상속 스트레스 하에서 시간 의존적 변형) 및 산화로 인해 분해됩니다.주요 고온 특성은:

- •

- 네크리프 파열 강도:650°C (1,202°F) 에서 T11은 ~140 MPa (~20,300 psi) 의 최소 100,000 시간 크리프 파열 강도를 나타내며 보일러와 원자로에서 장기적으로 사용하기에 적합합니다.

- •

- 네산화 저항성:크롬은 밀도가 높은 Cr2O3 스케일을 형성하여 더 많은 산소 확산을 억제하여 고온 증기 또는 연소 가스에 노출된 수 년 후에도 체중 감량 및 구조적 붕괴를 제한합니다.

- •

- 네열 피로 저항:낮은 열 팽창 계수 (~ 11.0 × 10-6 / °C) 및 높은 열 전도성 (~ 45 W / m · K) 은 순환적 인 난방 / 냉각 과정에서 내부 스트레스를 최소화하여 균열의 위험을 줄입니다.

- 네3. ASTM A213 T11 튜브의 제조 과정- 네

T11 튜브를 생산하는 것은 ASTM A213의 엄격한 차원 및 금속 요구 사항에 부합하는 것을 보장하기 위해 모든 단계에서 정밀도를 요구합니다. 프로세스는 일반적으로 다음과 같은 단계를 포함합니다.

- 네3.1 원자재 선택- 네

고 순수 철광석, 철폐 및 합금 원소 (Cr, Mo, Mn, 등) 는 구성 목표를 충족시키기 위해 공급됩니다. 낮은 불순물 수준 (P, S) 은 뜨거운 단과 같은 결함을 피하기 위해 중요합니다.

- 네3.2 녹음 및 정제- 네

- •

- 네1차 녹기:전기 활 오븐 (EAF) 또는 인덕션 오븐은 원료를 녹여서 초기 조성 조절을 달성합니다.

- •

- 네2차 정제: 라들 금속 (예를 들어, LF·Ladle Furnace) 및 진공 탈가스 (VD·Vacuum Degassing) 는 강철을 더 정제하여 황, 인산 및 용해 된 가스 (O2,H2) 순수성과 균일성을 향상시키기 위해.

- 네3.3 매듭 없는 튜브 형성- 네

T11 튜브는꿰매지 않는제품, 즉 용접 된 매듭이 존재하지 않습니다. 약점을 제거하고 균일한 강도를 보장합니다. 두 가지 주요 방법이 사용됩니다.

- •

- 네만네스만 프로세스 (고온 퓨싱):가열된 빌렛은 회전하는 망드렐로 구멍을 뚫어 홀 껍질을 만들고, 그 다음 롤링 및 스트레칭을 통해 벽 두께와 지름을 줄입니다.

- •

- 네푸시 벤치 프로세스 (냉면 필거 밀링): 더 작은 지름의 경우 가열 된 빗자루를 수압 롤을 사용하여 덩어리 위에 압축하여 점진적 인 축소로 정확한 크기를 얻습니다. - 네

3.4 열처리- 네

포스트 포메이션 열 처리는 미시 구조와 기계적 특성을 최적화하는 데 중요합니다.

- •

- 네정상화:980~1,040°C (1,800~1,900°F) 로 가열 후 공기 냉각 으로 곡물 구조 를 정제 하여 강도 와 견고성 을 높인다.

- •

- 네온화: 700~760°C (1,290~1,400°F) 로 ଉତ୍ତାପ하면 잔류 스트레스가 정상화되고 강도와 유연성을 균형있게 감소합니다. - 네

귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!  귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!